Hydrodemolition

The removal, demolition or hydroblasting of concrete or other materials with the force of ultra high water pressure is called Hydrodemolition.

The Problem

The demolition or partial removal of the concrete is generally done by jack hammers or milling machines. It creates a lot of dust, noise and it’s time consuming. But more important: it’s labor-intensive and the construction will be damaged. This damage is done by the chisel that creates micro cracks into the concrete and the steel reinforcement. The vibration causes the reinforcement to come loose from the concrete, even far from the point of impact. The damaged part will be larger, and thus, loses a part of the constructions strength.

The solution

The best way to partly remove, blast or demolish concrete without damaging the surrounding construction is Hydrodemolition. With this technique the concrete is selectively removed with ultra-high water pressure. It’s a dust free, vibration free and a time saving solution for the selective removal of different kind of concretes and other surfaces. The finished surface is perfectly prepared to bond with a new layer of concrete or paint.

Where could Hydrodemolition be used for?

- Removal of Refractory in boiler rooms or other installations. Also non-entry removal is possible;

- Removal of fixed anchors;

- Roughen concrete or other surfaces;

- The complete removal of the top layer to the right depth, with retaining the steel reinforcement;

- Damaged constructions by fire or excessive heat;

- Removal of painting without dust or the use of sandblasting;

- Removal of road markings.

Main advantages

- No dust;

- No damage to steel parts;

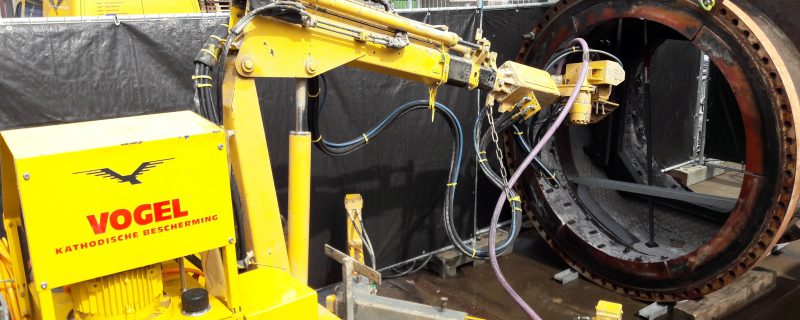

- With the use of robotics it can be used at a safe distance. Even non entry;

- Can be used in an high explosive zone due to no sparking;

- Vibration free for operator and construction;

- Avoids cracks in the material;

- Perfect finish for applying new material;

- Time saving and minimizing costs.

Impressie van onze hydrodemolition werkzaamheden: